Techmanrobot

Techman Robot (techmanrobot.com) designs and sells collaborative robot arms with built-in vision, user-friendly programming, and industry-oriented connectors for manufacturing, inspection, and pick-and-place tasks. Its hardware and software target small-to-medium manufacturers, integrators, and automation engineers who need accessible robotics with integrated sensing and out-of-the-box application templates.

What is techmanrobot.com

Techmanrobot.com is the official website and product portal for Techman Robot, a manufacturer of collaborative robots (cobots) that combine articulated robot arms with integrated vision systems and an accessible development environment. The company packages its hardware, software and optional accessories for factories and labs that need flexible automation without extensive robot programming expertise. The site offers product specifications, case studies, distributor contacts, and service/support information for Techman’s robot series.

Techman Robot machines are positioned between general industrial robot arms and consumer-grade automation: they provide industrial payloads and repeatability while exposing simplified interfaces, drag-and-drop programming, and built-in cameras. On the site you will find models oriented at light assembly, bin picking, visual inspection, screw driving, and collaborative tasks where humans and robots share workspaces. Techman Robot also publishes technical resources — datasheets, integration guides, and application notes — aimed at system integrators and maintenance teams.

The website serves buyers, integrators and engineers. Buyers use it to compare specifications and request quotations; integrators use technical downloads and contact points to plan deployments; engineers use the developer materials and API documentation to prototype vision-guided workflows and factory integration. For the latest product model details and firmware updates, check the official Techman Robot product pages and support sections on techmanrobot.com.

Techmanrobot.com features

What does techmanrobot.com do?

Techmanrobot.com presents the product lineup and capabilities of Techman Robot, enabling users to evaluate and procure collaborative robots with integrated vision and software. The site lists models with differing reach, payload and axis counts, and it details compatible end-effectors and accessories to adapt robots to common manufacturing tasks.

The platform highlights built-in features intended to reduce integration time: onboard cameras and image-processing functions for part detection, a graphical programming environment for sequence creation and teach-mode operation, and pre-configured application templates for pick-and-place, inspection and assembly. It also documents communication options such as Modbus, Ethernet/IP and fieldbus interfaces for PLC and factory integration.

Finally, the website organizes after-sales resources: firmware downloads, firmware release notes, spare parts ordering, service plans, and contact information for global distributors. Detailed technical documentation and case studies are provided so teams can assess performance, cycle times and sensor integration requirements before purchasing.

Techmanrobot.com pricing

Techman Robot offers these pricing plans:

- Starter: $25,000 one-time hardware purchase for entry-level cobot with basic support and standard accessories

- Professional: $35,000 one-time hardware purchase for mid-range cobot with extended vision options and 12-month standard support

- Enterprise: $65,000+ one-time hardware purchase for high-payload models and full enterprise support with installation assistance

- Maintenance Plan: $200/month or $2,000/year for active remote support, firmware updates and expedited spare parts access

Prices above reflect typical market ranges for collaborative robots with integrated vision and service packages; specific model costs vary by payload, reach, and optional accessories such as specialized grippers, conveyors, and force sensors. For accurate quotes, volume discounts, and regional pricing, consult the Techman Robot sales pages and authorized distributor listings on the official site. View Techman Robot hardware and support pricing on the company’s contact and product pages (https://www.techmanrobot.com).

How much is techmanrobot.com per month

Techmanrobot.com starts at approximately $200/month when amortizing low-tier maintenance and cloud/remote-support subscriptions rather than the robot hardware itself. Most customers purchase the robot as a capital expenditure and then subscribe to a monthly maintenance plan or optional remote support, which commonly ranges from $200/month for basic coverage to $1,000+/month for premium, on-site SLA packages.

Many integrators also offer leasing or financing arrangements that convert the upfront hardware cost into monthly payments; those monthly amounts depend on contract length, residual value and local financing rates. For precise monthly financing offers, contact Techman Robot sales or an authorized partner.

How much is techmanrobot.com per year

Techmanrobot.com costs around $2,000/year for an annual maintenance plan option that includes firmware updates, remote diagnostics, and priority support; this figure is separate from hardware purchase. If including a multi-year financing plan for the robot hardware, total yearly costs will reflect the amortized purchase price, support subscriptions, and consumables such as end-effectors and replacement parts.

Enterprises that opt for on-site installation, training and extended warranties should expect total ownership costs to increase by several thousand dollars per year depending on uptime requirements and spare-part inventories. Always request detailed total cost of ownership (TCO) projections from Techman Robot representatives.

How much is techmanrobot.com in general

Techmanrobot.com pricing ranges from approximately $25,000 to $65,000+ for hardware, plus subscription and service costs of $200/month to $1,000+/month. The lower bound typically covers entry-level cobots with smaller payloads and standard vision; the higher bound is for larger payload robots or bundles that include extended warranties, custom grippers, and onsite commissioning.

Total cost of ownership depends heavily on integration complexity, required cycle times, and facility safety modifications (fencing, sensors, interlocks) when deploying multiple units. For production planning, budget both the hardware and a realistic support and spare-parts allocation over a 3–5 year lifecycle.

What is techmanrobot.com used for

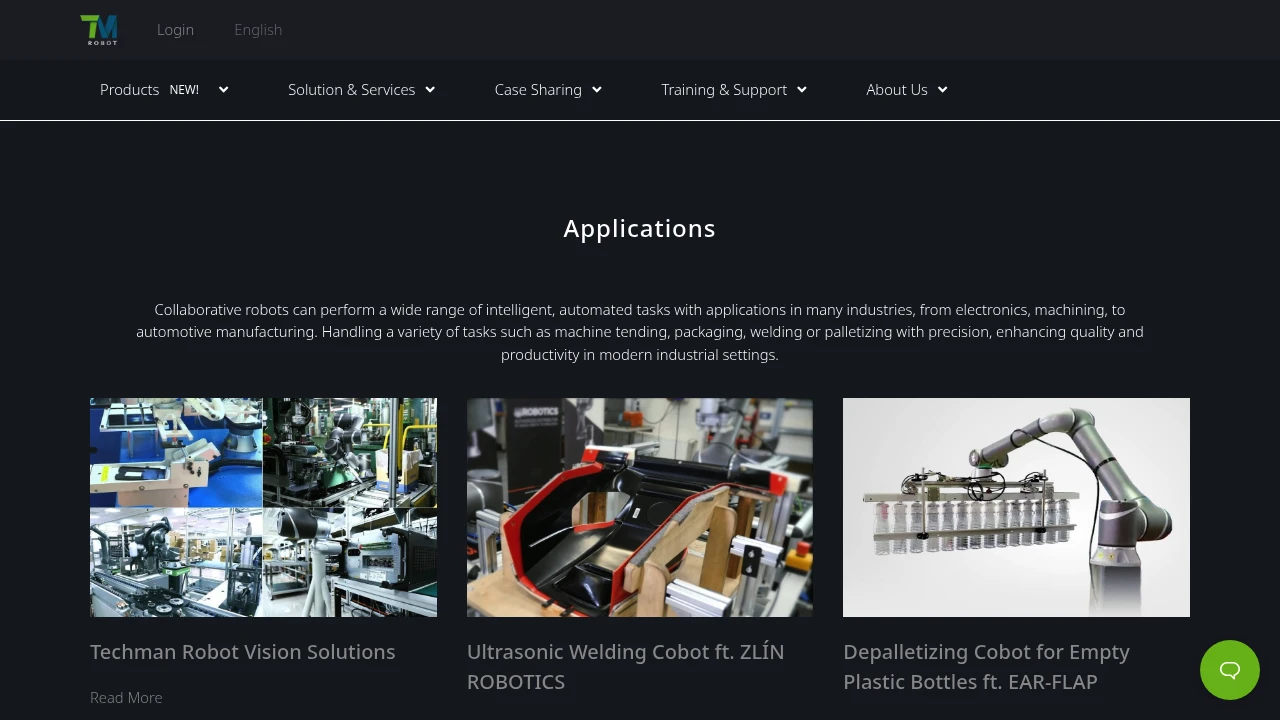

Techman Robot hardware and software are primarily used to perform repetitive industrial tasks where consistent positioning, visual verification, or safe human-robot collaboration is needed. Typical factory applications listed on the site include pick-and-place, machine tending, packaging, light assembly, screw-driving, and visual inspection. These use cases exploit the combination of robot motion and machine vision to replace tedious manual work or to supplement human operators.

Use-case breakdowns on the website show how integrated vision simplifies processes that otherwise require external cameras or complex fixturing. For example, bin picking workflows use onboard image processing to locate randomly oriented parts and compute grasp points in real time. Inspection tasks leverage high-resolution imaging and template matching to detect defects and route rejects.

The collaborative nature of Techman Robot models also supports shared workstations where safety-rated tools, speed & separation monitoring, or force-limited operation allow humans and robots to work in close proximity. This is useful for small-batch manufacturing and flexible production lines where fast changeovers matter.

Pros and cons of techmanrobot.com

Techman Robot systems offer specific advantages for many manufacturing teams. Strengths include integrated vision and an accessible programming environment that reduce integration time and lower the barrier for non-robotic engineers to create automation sequences. The compact, collaborative form factor is well-suited to small- to medium-sized enterprises that need flexible automation without heavy guarding.

Conversely, there are trade-offs. Collaborative cobots typically have lower payloads and smaller work envelopes than large industrial robots, which can limit throughput for heavy or large-part handling. Integrated vision is convenient but may be less flexible than a custom multi-camera vision system for highly specialized inspection tasks. Additionally, advanced customization and deep PLC integration occasionally require assistance from experienced integrators.

On the support side, regional availability of authorized service and spare parts can affect uptime, so global buyers should verify distributor coverage. Finally, while the programming environment is user-friendly for standard tasks, highly optimized cycle times or complex multi-robot coordination usually need specialist engineering.

Techmanrobot.com free trial

Techman Robot does not typically offer a software-only free trial for the full robot hardware, because the core product is physical machinery rather than a purely cloud-based service. However, the company and its distributors often provide interactive demos, on-site pilot programs, and loaner units for proof-of-concept projects to qualified customers. These pilots let teams validate cycle times and integration requirements before committing to a full purchase.

For software evaluation, Techman Robot sometimes provides simulator packages or demo versions of their programming environment so engineers can develop and test sequences offline. This simulator capability helps reduce commissioning time by allowing program verification prior to deploying the physical robot.

To arrange demonstrations or ask about pilot programs, use the Techman Robot contact channels and regional distributor pages on the official site to request a demo or loaner evaluation unit.

Is techmanrobot.com free

No, Techman Robot hardware is not free. The core product is capital equipment sold or leased to manufacturers; there are associated costs for hardware, installation, and optional support subscriptions. Software development tools may offer demo or simulator modes, but production use requires purchased hardware and support agreements.

Techmanrobot.com API

Techman Robot provides integration interfaces designed for factory automation and system integration. The API capabilities include TCP/IP and fieldbus interfaces for sending motion commands, reading status, and integrating robot events with PLCs or MES systems. Common industry protocols such as Modbus TCP, Ethernet/IP and OPC UA are often supported or available through gateway modules, enabling direct exchange of production data with existing automation stacks.

On the software side, Techman Robot exposes a programming environment with scripting hooks, vision SDKs, and Ethernet-based APIs that allow integrators to feed vision results, set I/O states, and trigger program flows. This makes it possible to implement custom pick strategies, coordinate multiple robots, and log production metrics to factory databases. The vendor’s developer documentation and SDK downloads on the product pages include API reference materials and sample code for common tasks.

For advanced integrations, the Techman Robot ecosystem supports MQTT or REST-style interfaces via middleware when connecting to cloud platforms or remote monitoring systems. Integrators commonly combine the robot’s native APIs with edge gateways to implement secure remote diagnostics and telemetry. Reference integration guides and the vision SDK are available from Techman Robot’s technical support area for authenticated customers and partners.

10 Techmanrobot.com alternatives

- Universal Robots — Lightweight, modular cobots with a large ecosystem of third-party grippers and certified accessories; strong global service network.

- ABB — Broad portfolio of industrial robots including collaborative and high-payload systems, with deep PLC and MES integration support.

- KUKA — Industrial and collaborative robots with high-precision motion control suitable for heavy manufacturing and automotive assembly.

- Fanuc — Established industrial robot supplier with high-cycle, high-uptime systems and a large global support footprint.

- Yaskawa — Motion- and robot-focused vendor with strong controls integration and proven industrial performance.

- Rethink Robotics — Historically focused on collaborative robots designed for safe human interaction and simple programming models.

- FANUC CRX — Collaborative variants of traditional FANUC robots aimed at safe human-robot collaboration in production.

- Omron — Integrated automation solutions combining sensing, control, and robotics for machine-level automation.

- EPSON Robots — SCARA and articulated robots focused on high-speed pick-and-place and electronics assembly.

- Frankaa Emika — Lightweight cobots and developer-friendly kits used in labs and small factories.

Paid alternatives to Techmanrobot.com

- Universal Robots — Known for intuitive programming and extensive partner ecosystem; priced as premium collaborative solutions with dealer services.

- ABB — Offers both collaborative and traditional industrial robots with comprehensive PLC and MES integration options and enterprise support contracts.

- KUKA — Strong for heavy-duty and high-precision use cases; integrates tightly with industrial control systems and factory planning tools.

- Fanuc — Offers high-speed, high-duty-cycle robots with proven longevity in production environments; strong spare parts and service network.

- Omron — Combines vision, sensing and robotics with machine automation platforms and industrial controls for turnkey solutions.

Open source alternatives to Techmanrobot.com

- ROS (Robot Operating System) — A flexible open-source robotics middleware that supports motion planning, perception stacks, and multi-robot coordination; used widely by researchers and integrators to build custom robotic applications.

- MoveIt — An open-source motion planning framework commonly used with ROS to handle kinematics, path planning and robot manipulation tasks.

- OpenRAVE — An open-source planning environment that supports robot modelling and motion planning; often used for research and advanced simulation.

- ROS-Industrial — An extension of ROS targeted at industrial hardware and factory-grade integration, with community-contributed drivers for many robot brands.

- Orocos — Open source real-time control framework for robotics; used in integrations that require deterministic control loops.

Frequently asked questions about Techmanrobot.com

What is Techmanrobot.com used for?

Techman Robot is used for collaborative manufacturing tasks such as pick-and-place, visual inspection, machine tending and light assembly. Its integrated vision and user-focused programming environment make it suitable for small-batch production and tasks that require quick changeovers. Manufacturers deploy these robots to reduce repetitive manual work, improve part consistency, and add visual verification to existing stations.

Does Techman Robot include integrated vision?

Yes, many Techman Robot models include built-in vision systems. The onboard cameras and image-processing tools support part detection, orientation estimation and defect inspection without the need for a separate vision system. This simplifies wiring and reduces integration time compared with external camera installations.

How much does Techman Robot cost to buy?

Techman Robot hardware typically starts around $25,000 and can exceed $65,000 depending on model and options. The final price depends on payload, reach, vision options, grippers and installation services. For exact pricing on specific models and configurations, request a quote through the official Techman Robot contact channels.

Is there a free trial or demo unit?

No, Techman Robot does not offer an open free trial for hardware, but authorized distributors often provide demos or pilot programs. Proof-of-concept loans, on-site demonstrations, and simulator software are common approaches to validate applications before purchase. Contact local distributors to arrange a live demo or pilot evaluation.

Can I program Techman Robot without coding experience?

Yes, the Techman Robot programming environment is designed to be accessible with graphical, teach-by-demonstration and template-based workflows. Users can create sequences with drag-and-drop blocks, record waypoints via teach pendant and use prebuilt vision templates for common tasks. Advanced users can still access scripting and API calls for customization.

What safety features do Techman Robot cobots have?

Techman Robot models include standard collaborative safety features such as force-limited operation, speed and separation monitoring, and configurable safety zones. These features are used alongside risk assessments to determine whether additional guarding or sensors are required. Safety certifications and local regulations should be confirmed for each deployment.

Does Techman Robot integrate with PLCs and factory systems?

Yes, Techman Robot supports industrial communication protocols for PLC and MES integration. Protocols like Modbus TCP, Ethernet/IP and OPC UA are commonly used to exchange status, I/O and production data, and SDKs or gateways enable communication with higher-level systems for coordinated automation.

Can Techman Robot perform bin picking?

Yes, Techman Robot supports bin-picking workflows using its vision capabilities and grasp computation tools. The integrated camera and image processing let the robot locate parts in randomly oriented bins, with typical implementations including suction cups or adaptive grippers for reliable picks.

How is Techman Robot maintained and supported?

Techman Robot offers maintenance plans that include firmware updates, remote diagnostics and spare parts access. Support tiers range from basic remote support to premium on-site SLAs; customers should verify distributor coverage for parts and field service in their region. Preventive maintenance schedules and spare-part lists are documented in the technical resources.

Where can I get SDKs and developer documentation?

Techman Robot provides developer resources including SDKs, API references and vision guides for integrators and partners. These materials are available through the technical support area and product pages on the official site, which contain downloads for firmware, sample code and integration examples.

techmanrobot.com careers

Techman Robot lists career opportunities and company information on the corporate and careers sections of techmanrobot.com. Job openings typically span product engineering, software/vision development, sales and regional service roles. Applicants seeking positions in robotics development or field service should consult the official careers pages for current listings and application procedures.

techmanrobot.com affiliate

Techman Robot operates through a network of authorized distributors and system integrators; affiliate or partnership programs are managed through regional sales offices. Companies interested in reseller or integration partnerships can contact Techman Robot via the official partner inquiry channels to learn about certification, training and commercial terms.

Where to find techmanrobot.com reviews

Independent reviews and case studies for Techman Robot can be found on industry trade publications, automation forums, and video platforms where integrators publish pilot results and deployment walkthroughs. For manufacturer-provided case studies and customer references, consult the Techman Robot success stories and resources sections on techmanrobot.com. External validation from system integrators and end-user testimonials helps assess real-world performance and support responsiveness.